DIY brick fence step by step instructions. Building a brick fence with your own hands

A brick fence, erected in accordance with all the rules, will serve as the most reliable protection against negative external influences and will decorate the house it protects, delighting the owners for many decades with its excellent security and aesthetic qualities.

Design solutions for building a brick fence

The design of brick fences can be with or without forging elements; made of colored bricks or painted later; The plain version is also available in a wide range of colors.

Elements such as forging and small sculptures on posts in the form of animals, vases, and cups that are ideologically attached to it look great in a fence-architectural ensemble. The selection of fence posts against the background of walls looks impressive due to their color or texture difference.

Finishing and plastering of such fences is carried out after they are completely dry after laying. First, the walls are moistened, then 150 mm thick plaster is applied, within an hour, this layer dries and is leveled with a long lath. The plaster dries for two days and is moistened with water to avoid cracking.

To understand the intricacies of brick fence construction, you need to know some information.

Choosing a brick ideal for laying a fence

Brick for building a fence photo

Today, using appropriate technologies, a huge number of brick options are produced, varying in composition and appearance. The well-known red brick is not only not the only suitable option for building and laying a fence, but also has many competitors that are in no way inferior to it in quality, appearance, durability and practicality.

The so-called decorative brick is widely represented on the market; it is most often used for fences as the most aesthetically acceptable option, allowing many color modifications.

Of course, no one will build a fence whose facade is made of ordinary rubble stone, used for rough masonry and partitions. Although the ground base of a fence can be made from such bricks, it is subsequently plastered or filled with cement in order to save designer bricks.

At a minimum, white sand-lime brick is used in the fence masonry.

Red brick fence may not have a dull solid color, but brick inserts of various colors, forming a certain pattern, captivating the eyes of passers-by and the owner with its design play.

Such a brick can be solid, hollow, or “super-efficient” hollow. They all differ in porosity, strength, frost resistance, density and color. All these properties can be viewed in a table on the Internet or found out directly from sellers.

Facing brick for fence construction

The facing brick itself is different, its properties manifest themselves differently in different climatic conditions. But the most resistant to atmospheric and physical influences is ceramic brick, which also has its own range of colors and cost, which is an order of magnitude higher than the cost of rough brick.

Yellow brick is the most popular in the brick design market. A fence lined with bright yellow brick attracts the human eye, and the color itself has a beneficial effect on the human psyche.

You can easily verify this by looking at the yellow brick fence, a photo of which can easily be found, if not on the next street, then on the first page of an Internet search engine - for sure.

Facing brick, like red brick, comes in several types with different properties and colors - facing and facing-glazed.

You can imitate designer masonry, consisting not only of one color, but of a whole ensemble of shades, by simply erecting a modern concrete fence, equipped with the appropriate pattern, and then plastered and decorated in a certain way.

Thus, there are three options for fence masonry from three different types of bricks - red, facing and frost-resistant.

- After completion of the masonry, the red brick needs plaster. Often this stage of work is deliberately omitted due to a certain design idea;

- in contrast, facing bricks are produced as a material that is absolutely ready for aesthetic perception without any post-construction processing;

- Frost-resistant brick, due to its maximum quality, will add a service life of several decades to the fence.

Tools and materials required for laying a fence

To build a brick fence with your own hands, the builder will need a set of many tools:

- a standard household set, including trowels, a grinder, a hammer, ropes, fittings, buckets, a shovel, levels and a tape measure.

— From consumables, you need to purchase bricks, sand, gravel, and collect water in advance.

- You should think in advance, based on the size of the future fence, whether it will be more convenient to pour the foundation - manually from containers or using a concrete mixer.

A few important points to remember

Tools for building a brick fence.

To build a fence with your own hands, you need to keep in mind the following points:

- The width of the fence posts can be 1, 5 or 2 bricks, respectively 380 mm and 50 mm. At the same time, the standard height of both options can be from 500 mm - and higher;

- the base of the fence begins in a half-meter trench, the fence should never stand on bare ground;

- the distance between the pillars varies from 2500 mm to 6000 mm;

- gates and fence gates must be equipped with their own additional posts;

- The evenness of the seams is controlled not visually, but with the help of a metal rod with a diameter of 8 or 10 mm, laid on the front edge of the freshly laid row and filled with cement. The rod is removed from the still soft solution immediately after laying out the next row;

- it is advisable to create additional fastening between the wall and the pillar by placing reinforcing mesh between them during the laying process every 3 to 4 fresh rows;

- Before laying begins, all bricks undergo a process of dipping in water. This will force the pores of the material to open and absorb maximum moisture to prevent its absorption from the foundation.

Settlement process

- Calculation of materials for building a fence manually should be done clearly and carefully.

- To calculate, you need to know the entire area of the future fence.

The total number of building brick units - the bricks themselves - is calculated per 1 m kV. masonry walls. For masonry with a thickness of .5 bricks this is 100 construction units, for a thickness of 2 bricks - about 200mm

Preparatory and foundation work

Laying out the foundation for a brick fence photo

Building a brick fence with your own hands begins with marking the foundation of the future fence with a tape measure, square, stakes and rope. The stakes are driven into the corners and along the walls of the future fence, and a rope is pulled along them. At this stage, all corners of the trench are also measured using a square. In the centers of the future pillars, two metal pins are placed in each - the height of the proposed fence.

The following stages are worth considering in more detail:

- Digging a trench. The trench should have a width of 600 - 700 mm more than the masonry line, and a depth of at least 800 - 1000 mm. Such a great depth is due to the weight of the future fence and foundation.

- In the second stage, the bottom of the trench is filled with sand, forming a layer of 100 mm, and compacted. This creates a drainage shock-absorbing cushion.

- Now the formwork is being built around the trench. The top edges of the horizontal boards should form a perfect straight line so that the concrete hardens as evenly and smoothly as possible.

- A reinforced layer is laid inside the trench. To do this, the reinforced mesh is rolled into a pipe with a diameter of at least 100 mm. The absence of this point in the work will lead to the appearance of fundamental cracks in the walls and frame, accelerating their already rapid destruction.

- The last final stage of working with the foundation is represented by pouring it with a solution consisting of 2 parts of cement, 4 parts of crushed stone, 3 portions of sand and water - the liquid consistency is determined by eye. The fresh foundation is leveled, pierced with reinforcement to release trapped air and left for 4 weeks to harden. If the weather is hot outside, the foundation is watered to prevent cracks from forming in it.

Construction of masonry

Laying a brick fence

A brick fence is erected with your own hands in several stages.

- The frozen foundation is covered with a waterproofing material - roofing felt or several layers of polyethylene. According to one technology, the pillars are laid out first, then the piers. Here we will consider the technology of parallel masonry along the entire perimeter of the fence.

- The first row of bricks is laid out, starting from the column. Cement is placed on the post with a trowel. The first 4 bricks are tried on in place. The empty space in the center of the column will be filled and filled with reinforcement.

Using two homemade L-shaped wooden slats in cross-section, the bricks are fixed in place, smeared with a cement compound and aligned with each other.

Using a straight rod, the height of the surfaces is leveled. This is how the first three rows are laid out.

- In parallel, the wall is laid in the same way on similar three rows.

- Now a metal mesh is placed between the column and the wall, filled with cement, and aligned to the overall height of the rows.

- The second, third and fourth points are repeated the required number of times.

- Filling the space with cement in the center of the posts.

Conclusion

Thus, it is clear that the construction DIY brick fence different types is not an easy matter. But the main difficulty in building a fence, as opposed to building the same house, lies not in calculating materials and drawing up a construction plan, but directly in practice - in the correct reinforcement of the base of the fence, timely control over the quality and uniformity of the fence masonry.

Disadvantages include the high cost of building materials and the complexity of construction. But despite this, if you try, you can create such a fence yourself. A brick fence built with your own hands must be of high quality and easy to use, so it is important to choose the option that is not only optimal in terms of complexity, but also to carry out thorough preparatory work, and to follow all technological rules during the construction process.

A brick fence is a strong and durable structure that is resistant to any natural influences. However, the cost of such a fence is quite high.

A brick fence is an elite type of fencing that has time-tested characteristics such as strength, durability, resistance to adverse natural influences and decorativeness.

Types of structures

Almost all types of brick fences have support pillars, which are the main element of the fence.

Almost all brick fences built with your own hands have support pillars that are laid in the foundation and lined with brick. They are the main element of the fence; then you can use various building materials to cover the spans or build a fence entirely from bricks alone.

A brick fence with forging is an exclusive and expensive way to construct a fence.

The type of brick fencing with a metal profile is quite popular. It will be cheaper to build than a solid brick one and it will look quite interesting.

A more expensive and exclusive option is a building with forged decorative elements. This type of fence is closer to the European style, where it has only a decorative function.

Also looking very nice is a fence built from bassoon brick, which is similar in texture to natural crushed stone. The cost of the material is quite high, but at the same time it is very resistant to weather conditions and can last for many years.

There are many different types of fences that you can build from brick with your own hands, and each of them has its own fans, advantages and disadvantages. But one thing is clear that any brick fence will perfectly perform its protective functions, emphasize the beauty of the home and improve any plot of land.

Required tools and materials

A concrete mixer will greatly facilitate the process of mixing the mortar for the foundation of a brick fence.

The process is quite expensive and labor-intensive. You will need a lot of tools and various auxiliary devices for work. We can highlight the main ones.

- Tools for earthworks: shovel, sledgehammer, large crowbar. All this will come in handy if difficulties arise with rocks in the ground that need to be removed.

Masonry tools: trowel, pick. Brick laying is carried out with their help. You will also need buckets for the solution.- Tools for taking measurements: plumb line, tape measure, laser or hydraulic level. They are necessary to make the fence beautiful and reliable.

- Concrete mixer. It may not be used, but in this case the concrete for the foundation and the mortar for laying bricks will have to be mixed with a shovel, which is a rather labor-intensive and time-consuming task.

- To reinforce the foundation you will need a landfill machine.

To build a brick fence with your own hands you need the following materials:

- the necessary materials from which the wall will be laid out;

- concrete for creating a foundation;

- reinforcement and rubble stone will be needed for reinforcement and backfilling of the foundation;

- mortar for brickwork.

Calculation of the amount of material and marking

The amount of brick required for a fence depends on the height of the fence, as well as the method of laying.

You can build a brick fence with your own hands from any type of this material; accordingly, the price of the fence will depend on this. Standard, sand-lime or facing bricks are used for construction. Before starting work, it is important to take into account that for a single wall laying you will need 100 bricks per square meter, and for a double wall – 200 bricks.

Next, you need to determine how tall and thick the fence will be. If the fence will serve only a decorative function, it can be built half a brick thick. Most often, brick fences are built with 1.5 or 2 bricks, rarely with 3. The height of the building varies from 0.5 to 3.5 m.

To determine the exact amount of material, it is necessary to measure the fenced area around the perimeter, and also not to lose sight of differences and features of the soil structure.

To accurately determine the required amount of material, you need to measure the fenced area around the perimeter and pay attention to differences and features of the soil structure. After this, you need to draw up a drawing of the future structure, with its help you can more accurately calculate the amount of consumables and building materials that will be required for the work.

The drawing must be provided with a certain step - they will make the fence rigid and stable.

In places where there are differences on the land plot, the strip foundation must be poured so as to perfectly level the base for the construction of the fence. You also need to determine in advance the type and location of the gate.

The territory is marked using a cord, tape measure and stakes. Pegs are driven in at the foundation site and a cord is pulled between them. At the same time, it is necessary to note the location of the gate, wicket and intermediate posts. It is important that all angles are perfectly straight. The span between the pillars can be from 3 to 6 m - this will depend on the thickness of the brick wall.

Foundation installation

To build a brick fence on flat terrain, a strip foundation is usually installed. When the terrain has differences and unevenness, it is better to build a columnar one.

Usually, with your own hands, you build a strip foundation on flat terrain. When the terrain has differences and unevenness, it is better to build a columnar one. The depth of the strip foundation is 40-50 cm. The width of the foundation depends on the type of brick, type of masonry, fence parameters and wall height.

Before erecting a brick fence and its foundation, it is necessary to draw up a clear plan. The construction site must have all the building materials that will be needed during the work process. The construction of the foundation is carried out in stages.

- First, a trench is prepared for it, which can be dug manually or using an excavator.

- A drainage layer of gravel and sand is placed at the bottom of the trench, which must be thoroughly watered and compacted.

- Concrete mixture is poured on top.

If the site is sloped, then you will need to make formwork from boards. The frame is laid according to the height of the structure. Next, half of the concrete is poured into the formwork, and after that the reinforcement is laid, and at the end everything is covered with the remaining concrete mixture.

After the concrete is poured, it must be pierced with a metal rod as often as possible to get rid of voids in the material. The finished foundation should be covered with rags and left until completely hardened for 7 days. To prepare concrete, cement, crushed stone and sand must be mixed in a ratio of 1:3:3. After a week, the formwork is removed and the finished base is treated with a waterproofing agent.

Bricklaying

The most popular masonry for a brick fence is single-row masonry. Combined and openwork masonry is also popular.

Brick laying is carried out using a cement mortar consisting of water, cement and sand. Typically, a brick fence is built with your own hands using single-row masonry. Combined, openwork masonry is also popular. If you plan to build a high fence, it is better to use double-row masonry.

Its main rule is strict adherence to the work order and high-quality dressing of seams. Masonry is performed in a certain sequence.

- The brick is pre-soaked in water for better adhesion of the materials.

Then it is laid in several rows along the foundation.- Orders are established in the corners using nails.

The mortar is applied to the brick with a trowel, and the excess is removed with a trowel.

During work, you need to monitor the level of the masonry; for this, stretched twine is used, or you can make a frame from boards and gradually move the horizontal board higher.- It is important that the same amount of mortar is laid between the rows; it must be carefully leveled before laying the next row. Excess solution must be removed immediately.

- When the bricklaying is completed, it is necessary to treat the seams using ordinary mortar or special protective or colored compounds.

Plastering a fence

It is not necessary to plaster a brick fence built by yourself, but if this type of work is planned, then the whole process will be as follows:

- before plastering it is necessary to moisten the walls;

- apply a layer of plaster approximately 15 mm thick;

- leave all the work for an hour;

- then level the plaster layer with a sharp-edged lath;

- it is important to moisten the surface over the next 2 days to avoid cracks in the plaster;

- At the end of the work, you need to moisten the surface with water and treat it with a plaster float.

If you follow the above instructions in detail, then such a labor-intensive process, at first glance, as building a brick fence with your own hands, will be within the power of any owner who wants to make a beautiful and reliable fence for his home or dacha.

A fence is a fencing around a pre-house or dacha area. It gives the owner of the house a feeling of security from strangers and unwanted glances, and serves as a way to isolate his territory. And on a dacha plot, such a fence, moreover, protects the yard from the neighbor’s livestock - animals love to feast on someone else’s garden. And, of course, the fence is an integral element of the overall design of the site.

Today, the construction market offers a wide selection of materials for the construction of these fences. The fence can be:

- brick,

- concrete,

- metal made of corrugated sheets,

- mesh made from chain-link mesh,

- wooden.

All these structures can be built with your own hands. Let's take a closer look at the construction of a brick fence. Such fencing is very popular among private landowners. A brick fence is reliable, durable, and fire resistant. He is not afraid of strong winds and other vagaries of nature. In addition, it does not require maintenance or constant updating. Necessary building materials include:

- brick

- reinforcing bars

- concrete mortar for foundation and brick laying. A solution of sand, crushed stone and cement is diluted. But you can use ready-made dry glue for concrete-based brickwork - it will greatly simplify construction and save time

From the working equipment you will need:

- roulette

- shovel

- nylon cord or twine

- household concrete mixer or construction mixer

- trowel, trowel, spatula

- container for diluting the solution

- gloves

Where to begin

Before starting construction, you must:

- make a competent calculation of the future fencing,

- draw up a visual plan diagram in which to indicate the dimensions and sketch the appearance of the planned building,

- mark the places planned for gates and gates and, of course, support pillars.

The average height of a brick fence should not exceed two meters. The number of bricks depends on the length of the fence and the width of the installation. Most often, these fences are built in half a brick. If the material is laid in one brick, then the fence can be increased to 2.5 meters.

Mandatory elements of a brick fence are supporting columns. They are placed at a distance of 2.5 meters from each other. Various bricks are used for installation:

- red hollow,

- facade,

- silicate.

Use of foam concrete, expanded clay blocks, etc. Not recommended. Firstly, the fence will not become stronger, and secondly, the costs of masonry and subsequent finishing of the facades will increase significantly.

Approximately 1 sq. m. of masonry in one brick will need 100 pieces of bricks, and in two - 200 pieces. The calculations have been made - we begin construction.

Construction stages

Almost any above-ground construction begins with a foundation. For a brick fence, a strip foundation is usually poured.

- Using a cord, tape measure and wooden stakes, mark the area to be filled with foundation. Places for gates, wickets and support pillars are marked on the ground.

- A trench approximately 0.3 -0.5 cm wide is dug along the stretched cord. It is leveled and covered with a thin layer of crushed stone. In places where support pillars are planned, the hole is dug twice as deep

- A formwork made of boards is constructed along the perimeter to control the precise vertical pouring of concrete

- Using wire, a metal lattice is knitted from reinforcement rods and placed in the trench.

- A metal pipe of approximately 2-2.5 meters with a diameter of 50-80 mm in the area of the support columns is positioned strictly vertically and attached to the reinforcement with wire

- Concrete solution is poured

The foundation is ready in about a week, the formwork is dismantled. Before you start laying bricks, prepare a solution - according to the instructions, concrete adhesive for brickwork is diluted with water. Laying bricks begins with lining the support pipes.

If you plan to work with cement, then the solution is mixed one to two (1 part cement, 2 parts sand) and diluted with water to a thick sour cream.

- The material is laid one and a half bricks thick around the pipe

- When applying the mortar to each subsequent row of brick, beginners are recommended to use straight metal tubes about 0.5 m long. Before applying the concrete mass, they are located along the perimeter of the previous row of bricks

- Apply a trowel around the pipe in an even layer of approximately 1-1.5 cm. Without going beyond the laid out metal tubes

- Brick laying is carried out according to the following scheme: the first brick is laid horizontally. In a circle, the next butt joint is placed next to it. The other two sides are laid in the same way.

- Using a level, the strict vertical and horizontal of the laid row is measured. Metal tubes are pulled out

- Subsequent rows of material are placed in the opposite direction to the previous one. So that the bricks of one row overlap the masonry seam of another

- And so all the support pillars are laid out to the top of the installed pipes

Then the walls of the fence are laid.

- It starts from the support pillar. If the masonry is one brick, then one row of bricks is laid parallel to each other on the leveled mortar with the wide side down, the smaller edge on the front side

- It is filled with mortar and covered with bricks in two rows. They are located perpendicular to the first row, also with the wide side down.

- And by alternating each brick row, the walls are built to the height of the pillars. For a decorative effect, the wall can be laid 2-3 rows lower than the supporting column. This method is called chain ligation

- A method is also used when the bricks of the second row are laid on the first row not in parallel, but with a shift of half a brick to the side.

Masonry with a thickness of 1.5 bricks is carried out in the same way, the pattern of the arrangement of the material changes

- A long line of bricks laid in rows looks at the façade. On the same surface, behind the first row, the second row is laid, resting against the first with its smallest edge

- The second row is the opposite. Bricks with the smaller edge forward are mounted on the front side, and the inner row is laid lengthwise

Finally, a protective cap is installed on the tops of the support pillars. They can be made of concrete, metal or finished with soft tiles. These elements serve to protect the inside of the pillars from destruction.

Today, a brick fence can be given a variety of decorative designs. This effect is achieved by combining bricks of different structures and color shades, inserting a diamond-shaped row into the masonry. Covering the façade of the fence with carved ceramic tiles or wild stone. But fences with forging elements are especially popular. They give the brick fence variety and lightness. Modern forging allows you to produce an element of any floral curls and geometric patterns. Forging is most often mounted on the top of the walls around the perimeter or as separate inserts in the form of parts in a fence, gate or wicket. At the top, holes with a diameter of 12-14 mm are drilled along the perimeter of the wall. Concrete is laid in them and finished forging is inserted. Forged elements in the fence walls themselves, or gates, are mounted between the seams during brick laying.

Useful tips for building a brick fence with your own hands

- Before you start building walls, you should protect the foundation with waterproofing. Treat it with appropriate impregnation, or put a layer of roofing felt before laying

- Before laying, it is recommended to soak the bricks in water until small bubbles stop coming out of them. This will increase the adhesion of the brick to the glue

- When building walls, it is important to maintain a strict vertical line. Therefore, you can build a wooden frame and strictly adhere to its level

- If you plan to decorate the top of the fence with a canopy made of corrugated sheets, you should first assemble wooden rafters and install them into the walls of the fence at a distance of 30-50 cm, depending on the width of the slope.

- A fence with a canopy made of ceramic tiles is easier to install. Cement is used to make a single or double slope fill along the upper edge, to which the tiles are subsequently glued.

- As a decorative design, paintable plaster is most optimal. This is an economical and durable way to improve the fence. No suspended structures can be used, as this reduces the strength of the structure.

And, by the way, a fence one brick thick can withstand a tangential blow from a passenger car, one and a half bricks thick can withstand a direct blow from a loaded gazelle, and three bricks thick is already an invincible fortress.

A properly built brick fence will serve for decades without any complaints, providing reliable protection from uninvited guests and weather disasters. You can handle the construction of this substantial building on your own. Read the provided guide and get started.

Set for work

We will lay the bricks on cement mortar. You can prepare it yourself: mix a portion of cement with three portions of sand and add water until a plastic viscous mass is obtained. If desired, add a plasticizer to the mixture - it will extend the life of the masonry. If your budget allows, instead of a homemade mortar, you can use a special ready-made mixture for brickwork - it’s faster and more convenient.

Selection and calculation of bricks

The fence can be laid out from different types of bricks.

Each option has its own characteristics, namely:

- the red brick will need to be plastered after the masonry is completed. However, often red brick fences remain unplastered according to the owners’ design plans;

- facing brick allows you to imitate a variety of materials and does not require finishing;

- Frost-resistant brick will allow you to get a fence of the highest quality with an extended service life.

Choose the type of brick based on your preferences and budget.

It is very simple to calculate the required amount of building material, but to do this you need to know the total area of the future fence. The dependence is as follows: when laying walls with 1 brick, it takes about 100 building elements to build 1 m2 of wall, when laying double bricks - about 200 pieces.

Before starting construction, you need to decide on the desired height and thickness of the fence. If the fence is being erected solely for decorative purposes, it can be built with half a brick, placing the elements with a long edge along the fence. When building with a whole brick, the products can be laid out with the long side across the fence.

If the fence will serve a protective role, it is better to build it with 1.5-2 bricks. Choose the height of the structure yourself. It can vary over a fairly wide range - from 50 cm to 3.5 m or more.

| Name | Average density, kg/m3 | Porosity, % | Frost resistance grade | Strength grade | Color |

|---|---|---|---|---|---|

| Solid brick | 1600-1900 | 9 | 15-50 | 75-300 | red |

| Hollow brick | 1000-1450 | 6-8 | 15-50 | 75-300 | light brown to dark red |

| Hollow brick "super-efficient" | 1100-1150 | 6-10 | 15-50 | 50-150 | shades of red |

| Facing brick | 1300-1450 | 6-14 | 27-75 | 75-250 | white to brown |

| Glazed or engobed facing brick | 1300-1450 | 6-14 | 27-75 | 75-250 | any |

To make the finished fence more stable and rigid, it is not erected with solid masonry, but in the form of pillars with walls between them. Typically, pillars are laid out in 2.5-6 meter increments, in accordance with the selected thickness and height of the walls. Additional brick pillars must be laid out in places where gates and gates are installed.

Decide on all of the above points and prepare a drawing of the fence indicating the exact dimensions of each structural element. The drawing will allow you to calculate the required amount of materials as accurately as possible and better navigate when performing masonry.

Prices for construction and facing bricks

Construction and facing bricks

Let's start marking the foundation. To do this, we use a tape measure, rods and rope.

We drive pegs in the corners and along the walls of the future trench in increments of up to 1 m. We stretch the rope between the rods. At the same stage, we mark the locations of the pillars, gates and gates.

We carefully check all the angles - they must be strictly straight. To check this parameter we use a square. It is very important to correct all detected deficiencies at the marking stage, because this will be much more difficult to do in the future.

Making the foundation

Let's start laying out the foundation.

First step. We dig a trench. We maintain the width 60-70 mm wider than the future masonry. We make the depth at least 80-100 cm - the masonry will weigh quite a lot, so it’s better to play it safe. We level the walls and bottom of the pit.

Second step. We fill the bottom of the trench with a 10-centimeter layer of sand. Carefully compact the pillow. The sand will act as drainage and shock absorber during seasonal soil movements.

Third step. We install the formwork. We align the boards so that after pouring the concrete, the top edge of the base is perfectly level.

Fourth step. We reinforce the foundation. To do this, we tie the steel rods using wire into a mesh according to the dimensions of the foundation. We lay the finished mesh on a compacted sand cushion.

Fifth step. Fill the trench. We buy the solution or prepare it from a portion of cement, 4-5 portions of crushed stone, 2-3 portions of sand and water. We carefully level the filling surface and pierce it with reinforcement in several places to remove excess air. We give the pouring 3-4 weeks to gain strength. The formwork can be dismantled at least 10 days after pouring. In hot weather, we spill concrete with water to prevent it from cracking.

Fence laying

Before laying, dip the bricks in water for about a minute. Thanks to this, the pores of the material will be filled with water, and it will not take moisture from the solution.

We first cover the frozen foundation with waterproofing material. Roofing material or thick polyethylene folded several times will do.

To make the fence as strong and reliable as possible, we will build a single solid structure along the entire planned length. There are technologies according to which the pillars are first laid out to their full height, and then the piers, but we will not consider them.

Fence laying sequence

The first row is the most important part of the work

The first row is the most important part of the work  Applying the device, using it as a limiter, we apply the mortar to the brick. Can be applied to laid or laid brick, depending on which one is more convenient

Applying the device, using it as a limiter, we apply the mortar to the brick. Can be applied to laid or laid brick, depending on which one is more convenient

First step. . To do this, we lay out the perimeter of the future pillar of 4 bricks, leaving free space between them. We will later fill the empty space with reinforcement and fill it with concrete. First, we lay out the columns to a height of 3 bricks.

Second step. We lay out the walls between the pillars at a similar height.

Third step. We connect the columns with the spans. To do this, we simultaneously lay pieces of reinforcement on the span and on the column. As a result, 2 steel rods should extend onto the piers on both sides of the pillar.

Fourth step. We raise the masonry to the height of three more bricks according to the same pattern. Let's reinforce again. Further, the laying of pillars and piers can be carried out together.

We work in the same order to the desired height: lay three rows, reinforce, again three rows, again reinforcement, etc.

In order for the masonry to be not only of high quality, but also beautiful, the seams between the bricks must be the same. This is done very simply:

- Additionally, we buy a round metal rod;

- we lay it on top of the laid out row of masonry - one rod on each long side of the brick.

Select the diameter of the rod in accordance with the desired thickness of the seam. It is not recommended to make seams thicker than 6 mm.

To make the task easier, you can fix the rods along their entire length using cement mortar. After laying out the fourth row of bricks, the lowest bar should be removed and used in the next row.

In conclusion, all that remains is to protect the masonry from precipitation and melt water. We do this with the help of ebbs and caps made of sheet metal. We put the caps on the posts, and fasten the ebbs to the wall section. To fix the mentioned products we use dowels.

Plastering the fence

First step. We moisturize the walls.

Second step. Apply about 1.5 cm thick.

Third step. Let the applied solution dry for an hour.

Fourth step. We level the plaster with a lath with sharp edges. We leave the finish to dry for two days. Periodically moisten the plaster with water to prevent it from cracking.

Fifth step. After two days, we wet the plaster again with water and treat it with a special grater.

You have become familiar with the proven and most effective method of erecting a brick fence. Follow the recommendations received, and everything will definitely work out.

Prices for popular types of plaster

Plaster

Find out how to build with step-by-step instructions in our new article.

Good luck!

Video - DIY brick fence

A fence built from a material such as brick is a solid, beautiful and, one might say, prestigious fencing of a private territory. How to build such a structure yourself is covered in the article. The instructions will help you better understand the construction process.

What types of brick fence are there?

The most common designs are:

- Brick fence with metal profile. In terms of price, it is much cheaper than one made from one material, and it looks quite interesting.

- A fence made of the so-called bassoon. Its texture is very close to natural stone. This kind of brick is endowed with high resistance to the destructive effects of precipitation, wind and other environmental factors, so the fence can last a long time. However, its appearance will change little.

- Construction with forged inserts. This option can be called a European classic. It looks very beautiful, but you will have to spend a lot of money on its construction.

Attention! The main element of a brick fence are pillars that act as supports. They are metal pipes laid in the foundation and lined with brick.

- Brick fencing with wooden sheet. By combining such materials you can get very interesting options. The weight of such a structure is not large, which means you don’t have to worry about additional reinforcements.

- The combination with a profiled sheet will also be easy. Such a fence, with proper care, can last for decades.

Tools and materials

When building a brick fence yourself, you will need some tools and auxiliary devices.

- Shovels and augers are useful for performing earthworks.

- A trowel and a pickaxe will be needed for DIY bricklaying.

- Tape measure, level, plumb thread - they are used to make markings.

- Concrete mixer - this unit will greatly facilitate the process of mixing cement and sand mortar.

- A welding machine or knitting tool and wire are used to reinforce the foundation.

Materials you will need:

- brickwork mortar, cement, sand;

- brick and, if necessary, materials for inserts;

- reinforcement and rubble stone for the foundation.

To calculate the necessary purchases, you should have accurate measurements, according to which a drawing of the future fence is made. In this case, you need to think about the location of the gate and wicket.

Attention! Before purchasing the main material, you should decide on the masonry option. For 1 m² of fence, one brick usually takes 100 blocks, and for the same area of masonry with two bricks – 200.

How to pour a foundation

The construction of a brick fence that is quite heavy requires laying a strong foundation. In order for the construction to end successfully and the fence to last for many years, you should adhere to the following rules for pouring the foundation:

- The trench under the base should be 10 cm wider than the planned fence.

- Its depth depends on the type of soil layers. In those places where sand and moving layers are excluded, 60-80 cm is sufficient.

- After the trench is ready, the places for the pillars should be marked. They should be located no more than 300 m from each other.

- Mark the installation locations for wickets and gates, taking into account that they should be framed by pillars.

- Piles are inserted into the holes made with a drill and filled with concrete.

- Wooden formwork should be installed 10-15 cm above the soil level. This is the optimal height for starting brickwork.

- Using metal reinforcement, a frame is created for pouring the solution. At the same time, in order to avoid ruptures, the rods are tied with wire.

- Concrete is poured. They are compacted tightly.

- A few days after the concrete has dried, work with brick begins.

Advice. To ensure that the fence does not become an obstacle to the flow of sedimentary water and that it does not accumulate on the site, it is better to make drain holes in the foundation by placing pipe sections in the solution. In this case, they should be inclined towards the street.

How to lay and complete construction

The laying of the fence must be treated with special attention. The appearance and strength of the structure completely depends on the accuracy of its implementation.

- Hardened concrete is protected from moisture using film or roofing felt.

- Along the entire length of the foundation, a guide is laid in the form of a stretched thread in order to lay out each row evenly. It should be taken into account that the fence must be in the middle of the base.

- Begin laying, periodically checking the vertical level.

Advice. When working with facing material, it is better to use a rubber spatula. This tool will allow you to dirty the fence less. If the brick still gets dirty with mortar, you should wipe it with a damp sponge as quickly as possible.

- When laying brick blocks around the pipes, they are walled from the inside.

- If installation of additional elements is required, they should be tied in the masonry in at least 2 rows.

- To make the fence strong, metal wire is placed every 3-4 rows.

- Possible defects in work are checked after every 5th row. This is done using a rope stretched from the bottom corner of one edge to the top corner of the other.

- In conclusion, the work is carried out to protect the structure from moisture and undo the seams. Some nuances of building a brick fence can be learned from the attached video.

Advice. You can add dye to the cement mixture to seal joints. The result is a very interesting combination of colors.

Building a brick fence is a very responsible and labor-intensive task. To ensure that when building a fence with your own hands, the result does not disappoint, you need to take accurate measurements and work without deviating from the instructions.

DIY brick fence: video

Latest site materials

Water supply

Delivery agreement with deferred payment

You write" Since the contract directly states that the deferred payment is a commercial loan, the supplier is obliged to charge interest on the loan on the basis of clause 2 of Article 823 of the Civil Code of the Russian Federation, according to which the rules of

Heating

Indirect income tax expenses

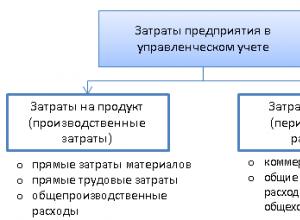

Direct costs of an enterprise The classification of direct costs of an enterprise includes those expenses that can be easily attributed to a specific cost object (service, product, project). Such costs include materials, raw materials that directly

Plumbing

New MTPL policy What MTPL forms are available from July 1

In Russia, the modernization of the car insurance system continues. Experts talk about the new rules for compulsory motor liability insurance and the new form of the form. Car insurers warn: from July 1, 2018, the next stage of modernization of compulsory motor liability insurance begins, which, first of all,

Pipes

When do you need to pay transport tax? Who calculates the payment amount and how?

The Kv coefficient is a calculated declaration indicator, determined based on the months of ownership of the vehicle. This article will tell you how not to make mistakes when calculating it. By incorrectly determining the coefficient Kv, legal entities may pay a transport fee

Plumbing

Wall interpretation of the dream book

Dream Interpretation of the 21st Century Why do you dream about the Wall and what does it mean: Climbing over a wall in a dream means in reality achieving a solid position. Jumping from it means an unjustified risk. Breaking or destroying a wall means misfortune, for which you yourself will be to blame. If in a dream

Heating

Pregnant deceased woman Seeing a pregnant deceased woman in a dream

Why does a pregnant woman dream of a dead person? In the land of dreams, you can easily meet a person who has died and talk to him. Why did a pregnant woman dream about a dead man? If a pregnant woman sees a deceased person, you should wait for a change in the weather. This interpretation is found in