Profiled planter membranes. Planter Standard, profiled membrane: description, technical characteristics and installation features Installation of the planter membrane

-

PLANTER Standard

A business-class product, the ideally selected physical and mechanical characteristics of which allow you to achieve the best balance of strength and flexibility of the material. Profiled membrane PLANTER- This is a high-density polyethylene (HPDE) sheet with molded round protrusions 8 mm high. The surface of the material effectively distributes soil pressure over the entire area of the base or foundation of buildings and structures. This eliminates the formation of local (point) loads.

Applicable

Buy -

PLANTER Extra

Profiled membrane It is characterized by increased mechanical strength and is used under conditions of increased operating loads. Profiled membrane PLANTER Made from high density polyethylene with molded spikes 8 mm high. PLANTER has high strength characteristics and is also resistant to chemical aggression, mold, bacteria and plant roots.

Applicable to protect waterproofing from mechanical damage, protect the foundation slab from capillary moisture, sanitize damp walls, prepare the base for the foundation slab and waterproof the blind area.

Buy -

PLANTER Eco

The membrane is ideal for use on private low-rise construction sites due to its light weight and ease of installation, where, as a rule, the material is subject to low operating loads. The surface of the material effectively distributes soil pressure over the entire area of the base or foundation of buildings and structures. This eliminates the formation of local (point) loads. Main function of membranes PLANTER eco- protection of the waterproofing layer of foundations and foundation slab.

Applicable to protect the waterproofing of mechanical damage, protect the foundation slab from capillary moisture, sanitize damp walls, prepare the base for the foundation slab and waterproof the blind area.

Buy -

PLANTER Geo (Planter Geo)

Profiled membranePLANTER geo– this is a fabric made of high-density polyethylene (HDP) with a spike height of 8 mm, with a layer of thermally bonded geotextile glued to it. Effectively protects foundation walls from moisture and basements from dampness, and also serves for the primary collection and drainage of water from the roof surface. Thanks to the protrusions on the surface of the membrane, channels are formed for rapid drainage of water. The membrane consists of two levels: geotextiles collect water, and drainage channels direct it.

Applicable for organizing horizontal and vertical drainage during the construction of foundations and as a drainage, protective, separation and root protection layer in flat roof structures.

Buy -

PLANTER Extra Geo

Profiled membranePLANTER extra geo– this is a canvas made of high-density polyethylene (HDP) with a spike height of 8 mm with a layer of thermally bonded geotextile glued to it. Effectively protects foundation walls from moisture and basements from dampness, and also serves for the primary collection and drainage of water from the roof surface. Thanks to the protrusions on the surface of the membrane, channels are formed for rapid drainage of water. The membrane consists of two levels: geotextiles collect water, and drainage channels direct it.

Applicable for facilities with increased requirements for reliability and safety, including:

Buy

- Structures with a depth of 2 to 10 meters. For example, multi-level parking lots or military and strategically important government facilities;

- Open tunnels;

- Premium-class buildings with maintained or “green” roofs, as well as roofs of underground parking lots (stylobates);

- Structures of all types with a reservoir drainage system, incl. residential and office centers, airfields, solid waste landfills, stadiums and others.

| Indicator name | Unit measurements | PLANTER extra | PLANTER standard | PLANTER eco | PLANTER geo | PLANTER extra geo | Test method |

|---|---|---|---|---|---|---|---|

| Blade thickness | mm | 0,8 | 0,55 | 0,55 | 0,6 | 0,8 | GOST EN 1849-2-2011 |

| Projection height | mm | 7,5 | 7,5 | 7,5 | 8 | 7,5 | GOST EN 1849-2-2011 |

| Weight 1m, not less | kg | 0,8 | 0,55 | 0,45 | 0,65 | 0,9 | GOST EN 1849-2-2011 |

| Compressive strength | kPA | 550 | 280 | 200 | 350 | 580 | GOST 17177-94 |

| Maximum tensile force, no less, method A along the roll across the roll | H/50 mm | 450

450 | 280

280 | 200

200 | 420

420 | 590

590 | GOST 31899-2-2011 |

| Relative elongation at maximum tensile force, not less | % | 18 | 20 | 20 | 30 | 18 | GOST 31899-2-2011 |

| Resistance to static punching, method B, not less | kg | 20 | GOST EN 12730-2011 | ||||

| Flexibility on a beam with a radius of 5 mm at low temperatures, no more | °C | Minus 45 | GOST 2678-94 | ||||

| Water absorption by mass | % | 1 | GOST 2678-94 | ||||

Plfnter are one- and two-layer universal polymer membranes used in industrial, civil, transport and hydraulic engineering. Membranes are made by forming raw materials from high-density polyethylene (HDPE) into a single sheet. The entire area of the front surface of the membranes is made in the form of cone-shaped protrusions 8 mm high and geotextile material attached to them (for certain brands).

Profiled Planter membranes and components

Profiled Planter/Planter membranes produced by TechnoNIKOL help preserve expensive foundation waterproofing without damage for more than 50 years. There are several types of membranes in the Planter family of profiled membranes:

- Planter Standard 2x20 m

- Planter Geo 2x15 m (with ketextile drainage layer)

- Planter Eco 2x20 m (lower specific gravity)

- Planter Extra 2x20 m

- Planter Extra Geo 2x15 m

Installation of membranes does not require professional skills and they are cheaper than their imported counterparts.

| Material grade | Density kg/m² | Roll size, m | Price per 1m², rub. | Application |

|---|---|---|---|---|

| extra | 0,8 | 2.0 x 20 | - | for the protection of waterproofing, protection of the foundation slab, during the construction and reconstruction of highways and slopes |

| standard | 0,55 | 2.0 x 20 | from 83.20 | for waterproofing protection of buried parts of buildings, rehabilitation of damp walls, protection of foundation slabs, when replacing concrete preparation |

| eco | 0,45 | 2.0 x 20 | from 72.40 | to protect the waterproofing of the foundation layer and foundation slab from capillary moisture |

| geo | 0,6 | 2.0 x 15 | from 149.00 | for organizing drainage and protecting waterproofing during foundation construction |

| Material grade | Unit | Size | Unit price, rub. | Application |

| PLANTERBAND | video clip | 12.5cm x 10m | - | for connecting PLANTER protective drainage membranes to each other. |

| video clip | 10cm x 10m | from 445.00 | ||

| PLANTERBAND DUO | video clip | 5cm x 10m | 299.6 | for connecting PLANTER protective drainage membranes to each other. The best solution for connecting flat edge membranes and PLANTER geo. |

| Fasteners PLANTER KREP (150 pcs/pack) | thing | 50mm | 9,00 | for mechanical fastening of the PLANTER protective drainage membrane. Can be used for fixation in concrete, brick and other hard materials. |

| PLANTER profile | linear meter | 7cm x 2m | 64.2 | for mechanical fastening of the PLANTER protective-drainage membrane above the waterproofing level on a vertical wall. |

| Support for TechnoNIKOL reinforcement s/s | thing | 35- 50mm | 2.9 | provides a thickness of the protective layer of reinforcement of 35 or 50 mm. Installation without a stand is possible if there is a rigid base - concrete screed, fine gravel. |

| Support stand for TechnoNIKOL | thing | - | 2.6 | If the support is installed on loose bases, waterproofing and profiled PLANTER membrane, a stand is required. |

Application of Planter membranes

Profiled membranesare used in industrial construction and private housing construction when installing foundation waterproofing and save time during its installation at sites, thanks to its simplicity and convenient roll sizes. Membranes also allow you to save up to 30% of money when replacing concrete preparation. The membranes last for more than 50 years, which makes it possible to do without expensive repairs of insulated surfaces for a long time.

Planter membranes are also used in the construction of tunnels, overpasses, underground parking lots and parking lots, i.e. where reliable and long-term waterproofing of the underground parts of the structure is necessary.

In private housing construction for:

- installations of drainage systems;

- replacement of concrete preparation;

- repair of internal walls;

- drainage devices under paving slabs;

In industrial construction for:

- installations of drainage systems;

- replacement of concrete preparation;

- protection of foundation waterproofing;

- devices for horizontal reservoir drainage in exploited roofs;

- "wall in soil" systems.

Technical characteristics of Planter membranes

Planter technology for laying profiled membranes

Planter membranes protect both vertical and horizontal surfaces. When installed on vertical surfaces, the membrane is positioned with its protrusions inward, i.e., towards the wall. Thanks to them, air circulation is ensured near the wall, and it always remains dry. If installation is carried out inside a building, then any sheet finishing materials (, plasterboard or plaster mesh) can be mounted on top of the membrane. Installation is carried out mechanically - with concrete dowels along the entire perimeter of the insulated surface or using special metal clamping strips.

All products in this series can be used in various regions of our country. Membranes can withstand low temperatures, exposure to UV radiation, and humid and aggressive environments for a long time. From a wide variety of membranes, you can choose the one that is best suited for solving a specific problem.

Related materials

In our warehouses you can buy building materials for the entire cycle of construction and finishing of your facility from foundation to roof. Together with membranes, we offer a complete list of materials for waterproofing and insulating building foundations. Once you have properly waterproofed and drained the foundation of your house, you will live in a dry and comfortable home for many years.

BUY IN ONE PLACE, SAVE ON DELIVERY, TAKE USE OF REGULAR CUSTOMER DISCOUNTS

Most interruptions in the operation of waterproofing directly depend on the wrong choice of design solutions.

Incorrect selection of materials does not provide maximum protection from moisture, incorrect installation work violates all operating rules. In order to reduce the risk of these problems, you need to choose the right technical waterproofing solutions that will eliminate water leaks, and as a result, significantly reduce the cost of restoring the waterproofing system.

Only some materials offered on the construction market can provide complete protective function against groundwater, moisture, and condensation. It’s not for nothing that the planter is called a protective membrane. This type of waterproofing allows dehydration of all surfaces, regardless of how it is located - horizontally or vertically. This waterproofing layer consists of very high density polyethylene. It can be a really strong barrier to any liquid - be it condensation or moisture. Installing a planter, that is, installing a protective membrane, is not at all difficult and anyone can do it. Convenient because it is packaged in rolls. It is easy and simple to deliver to the place where construction is taking place. The membrane sheets are equipped with round protrusions. They act as an obstacle between the surface and the protective layer itself. The planter is laid directly on the surface of the foundation, or, for example, flooring. Attached using various special materials. Can be fixed to bitumen mastic.

The planter membrane is used for absolutely all types, sizes of foundations, as well as types of buildings - be it a greenhouse or a hypermarket. Groundwater and condensation have the same negative effect on any foundation. Concrete mortar, no matter how expensive or high-quality it is, will lose its properties over time if it is not protected from water. In addition to all of the above, constant moisture leads to mold, which is almost impossible to remove. The ancient Romans, seeing mold stains in their houses, burned them. This fungus leads to irreversible consequences in the human body. Based on everything, maximum protection should be applied to the waterproofing system of any room, especially in crowded places.

Planter installation

In order to prevent groundwater and runoff from creating a greenhouse effect during the construction of the foundation, a planter should be used for waterproofing.

After the concrete frame is erected, its walls must be thoroughly sanded and coated with a layer of heated bitumen mastic. Particular attention should be paid to visible cracks. Then, on the created base, planter sheets are placed vertically. Installation (installation) of the waterproofing system is carried out directly on the mastic using dowels. The next stage is to apply the mounting mesh for subsequent finishing of the facade. When a compactor is laid instead of a concrete-cement mortar, first, it is necessary to compact a 10-15 cm layer of sand in such a way that no shoe marks remain, that is, the sand should be as hard as possible. After this, the same layer of crushed stone is poured so that the groundwater level does not rise. Only after these activities the installation of the planter begins. Sheets are laid only with overlap. To achieve maximum protection from water and moisture, the joints are connected to each other with bitumen-rubber tape. In this case, a moisture barrier is provided.

In addition, uniform distribution of soil pressure is also guaranteed.

Planter laying

The most common way to waterproof a home or future store is with high-density polyethylene, called planter. It is very convenient to use, thus it is used quite widely, both by ordinary summer residents and by those people who want to build a large premises, for example, a health center with a swimming pool or a large supermarket.

Installation of the planter can be done by hand, without the help of builders.

The most important thing is to know some rules for installing this waterproofing material. Sheets can be laid on both horizontal and vertical surfaces. In the second case, you will need special installation tools. But styling a planter is such an easy task that any man can do it. The sealant sheets are laid with their convex sides facing the surface, and not vice versa. This is necessary so that air circulates between the surface and the planter. The next, very important aspect is the fastening of the joints, because the sheets should only be laid out overlapping. Using a special tape, they are held together without much effort.

This waterproofing layer is guaranteed to prevent moisture from penetrating through it into the walls.

When starting the construction of a house or premises, a warehouse, any owner always thinks about how to ensure that the building is reliable and lasts for hundreds of years.

An important, perhaps even the most important thing in the strength of a building is its foundation - the foundation. It is this skeleton that holds the entire structure.

The foundation can be destroyed and deformed from moisture and sun. Many existing waterproofing methods protect the frame by only 30%.

For maximum protection from harmful environmental factors, a high-density polyethylene fabric called the Planter membrane was developed. Molded round protrusions, which are located throughout the entire canvas, evenly distribute soil pressure along the entire perimeter of the structure.

In the space between the membrane and the surface, which is isolated from moisture and water, air moves freely, which does not allow condensation to settle on the walls.

Various insulation materials or concrete screeds deteriorate over time; cracks appear on their surface, through which the roots of plants, even trees, grow. Unlike such insulators, Planter prevents the germination of vegetation. Due to the high density, cracks do not occur on the surface of the membrane.

Many private houses, large warehouses, and store buildings have basements. By isolating the foundation with a membrane, basements are protected not only from moisture. The waterproofing layer acts as insulation and helps maintain the same air temperature, despite the weather conditions and time of year.

Humidity is harmful to walls, foundations, and also directly affects humans.

When moisture gets on the walls, it becomes an excellent soil for the development of bacteria and fungi.

Mold is dangerous to health and the human body. Against this background, diseases such as tuberculosis and asthma arise.

Therefore, it is necessary to warn and ensure that harmful fungi do not arise at the beginning of construction. In addition, if the future building is intended for trade, the mold will instantly “eat up” all the products and it will no longer be possible to remove it, despite the variety of chemical detergents.

If the foundation is waterproofed with a Planter membrane, all the troubles described above can be avoided. It does not allow moisture to pass through and is a reliable protector for the structure of the building. Concrete, like brick, cracks over time under the influence of negative environmental factors. This can lead not only to the appearance and growth of fungus, but also to the complete destruction of the building.

In addition to moisture, the components of the foundation are affected by the sun's rays. When they hit the surface, especially in hot summers, building materials dry out and also crack.

The Planter membrane is made of high-density polyethylene, so the sun's rays do not penetrate through it. Ultraviolet radiation does not harm this waterproofing layer.

Planter membrane is widely used in construction. Foreign construction companies have long switched to this environmentally friendly and reliable material. Maximum protection against moisture is the most important function of the membrane.

Such a beautiful name was not invented in vain, because this waterproofing sheet is like a shell that covers the foundation. It is also widely used instead of concrete screeds, which significantly saves time and money.

The waiting time for the concrete solution to harden is 10-12 days in good sunny weather. Laying Planter will take no more than a day, even for the perimeter of a large room.

To waterproof the skeleton of a building, especially for swimming pools, sports complexes, saunas, this particular sealant should be used, because the water that is inside the building also sometimes leaks, seeps through cracks and small deformations, and from the outside the foundation is influenced by soil water.

To waterproof the skeleton of a building, especially for swimming pools, sports complexes, saunas, this particular sealant should be used, because the water that is inside the building also sometimes leaks, seeps through cracks and small deformations, and from the outside the foundation is influenced by soil water.

In addition, the soil on which the foundation is built does not always have ideal characteristics. Existing permafrost soils contain large amounts of ice, which begins to melt as temperatures rise.

For foundations installed on such soil, only Planter membrane should be used. Otherwise, wet walls and foundations will collapse within a few years.

When laying a polyethylene sheet instead of concrete, which will harden for a very long time in such conditions, as well as when installing a membrane on vertical foundation surfaces, the owner of the construction site and the future building can be sure that the building will be inherited by his great-grandchildren.

In addition to construction applications, Planter is widely used in shipbuilding.

The metal from which ships are made is in constant contact with water. No matter what primers are used to cover a metal surface, it still becomes unusable over time. Salt water will corrode any chemical treatments.

Recently, the Planter membrane has been used for waterproofing ship walls. It greatly increases and extends the service life, allowing you not to destroy the metal. This waterproofing layer is also used for drainage systems, helping to remove unnecessary and accumulated moisture. The air in free circulation between the surface and the canvas perfectly dries all the condensation that collects.

Features of Planter Standard professional membrane

The features of Planter Standard include, first of all, the fact that it is made of environmentally friendly polyethylene. Thus, it does not affect the human body and its health. Working with this waterproofing material is much easier, faster and more convenient than with other insulating manufactories. Polyethylene has a very high degree of density, which allows maximum protection of any surface from moisture, which is hated in construction.

Water is life, but in some cases it brings destruction and poses a great threat to the human body.

Planter Standard provides complete protection from the effects of water on building surfaces, thereby guaranteeing not only protection from destruction, but also the opportunity to have good health.

Another feature of Planter Standard is its economical packaging. The rolls in which it is packaged are compact, which significantly affects its delivery from a store or warehouse. Even an ordinary summer resident who decided to build a greenhouse is able to transport the rolls in a passenger car.

At the same time, the equipment exists both for small spaces and for huge construction perimeters. Saving time and money when laying a waterproofing layer are the main features of this material.

Specifications

The weight of 2 sq.m of Planter membrane is 1 kg. The protrusions (spikes) have a standard height of 8 mm. This height is ideal to ensure normal air circulation.

The sizes of the rolls range from two meters to twenty, depending on the size of the foundation. That is, you can purchase either a small roll for waterproofing, for example, a private home, or for large warehouses.

It has a high density polyethylene fabric - 280 kN/m2. The breaking force indicator is not less than 300 N.

As for water carrying capacity, its indicator is negative. Planter Standard does not allow moisture to pass through under any circumstances. When laying Planter, all operating rules must be followed. Only in this case will the waterproofing sheet perform its function correctly.

If cracks appear on the foundation over time, do not blame the waterproofing material. This only means that mistakes were made when laying it out.

In the gap between the surfaces and the waterproofing layer, air circulates in a volume 5.5 l/m2. Elongation at break is no less than 20% . The temperature at which work can be carried out with Planter is from minus 50 degrees to plus 70. Water absorption - no less 1% . Fire safety class indicator - KM5 (G4, V3, RP2). Tested and verified by GOST 2678-94 method.

Buy Planter Standard membrane in Moscow at a low price

Price for Planter Standard in Moscow depends on the quantity of goods purchased. For wholesale buyers, as well as regular customers, there is a system of discounts that will suit even the most capricious customers.

The most important thing is a trusted manufacturer and supplier who will ensure timely delivery without mechanical damage to the rolls.

By purchasing a waterproofing sealant, a person will in any case save money.

You can check your money savings using a regular calculation. Concrete mortar (that is, its components) is much more expensive, but does not provide protection against water penetration. Planter, especially for large rooms, is beneficial both in price and in terms of installation time.

To find out prices for this material in Moscow, you can ask for help directly from a store that works directly with suppliers or call by phone. For convenience, the Nova GEOMATERIALS company has created a website on which all price lists are available online.

This is very convenient because you can find out the wholesale and retail prices without leaving your home. You should be careful when choosing a supplier, because many scammers, having clandestine factories, produce low-quality, counterfeit goods. We provide all the necessary quality certificates.

Membrane PLANTER– geosynthetic material produced by TechnoNIKOL. TechnoNIKOL is the largest supplier of waterproofing materials and roofing coatings.

Types of Planter membrane:

- PLANTER eco

- PLANTER geo

- PLANTER standard

The Planter membrane is made from high-density polyethylene (HDPE). It is a surface with rounded protrusions, the diameter of which is 8 mm.

A layer of thermally bonded geotextile is additionally attached to the PLANTER geo membrane on top. This layer prevents silting of the material.

Due to its unusual structure (with protrusions), when pressure is applied to the Planter membrane, it is evenly distributed over the entire area. In this case, individual point loads are completely eliminated.

Protrusions on the surface of the membrane promote free air circulation between the canvas and the wall, normalizing the temperature and humidity conditions of the room.

Planter is a very durable membrane that is resistant to aggressive (chemical) environments, mold, bacteria, and ultraviolet radiation.

When used, two options for the location of the membrane are possible - vertical and horizontal. To connect individual membrane sheets together, welding is used along the flat edge of the membrane.

Field of application of Planter membrane

PLANTER geo:- Manufacturing of wall drainage

- Creation of drainage in exploited roofs

- Protection of waterproofing coatings

- Replacement of concrete preparation

- Rehabilitation of damp walls from the outside and inside of the building

Latest site materials

cesspool

Why do you dream about a cat - interpretation of sleep from dream books

Dream Interpretation of G. Miller Why do you dream of a Cat - psychological interpretation: Cat - If a woman dreams of a charming, fluffy, white kitten, this is an omen for her that, through clever deception, she will be lured into a trap set for her, but her health

Heating

How to correctly draw up an act of acceptance and transfer of an apartment after concluding a purchase and sale agreement?

The actual transfer of the apartment by the seller to the buyer and its acceptance is recorded in the acceptance certificate. The obligation to draw up this document is contained in Article 556. Civil Code of the Russian Federation. The act of acceptance and transfer of an apartment purchased on the secondary market usually has a simplified structure

Projects

Evgeny Osin died - biography, family and personal life, what he was sick with, cause of death Singer Evgeny Osin biography

Evgeny Viktorovich Osin. Born on October 4, 1964 in Moscow - died on November 17, 2018 in Moscow. Russian singer, musician, songwriter. Father - Viktor Osin, worked as a trolleybus driver. Has a younger sister Albina. His uncle was a drummer in

Pipes

What is the meaning of human life: a view from philosophy, religion and psychology

Aristotle Many people ask the question - what is the meaning of life? And then they diligently search for the answer to this question, studying a variety of opinions of famous and not so famous people, which can be found in numerous sources of information. And there are many opinions on this matter

Heating

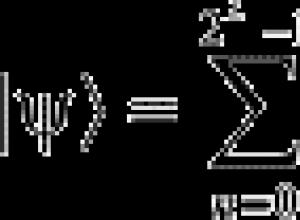

A Brief Introduction to Quantum Computing (guest post by Roman Dushkin)

The content of the concept of “quantum parallelism” can be revealed as follows: “The data in the calculation process represents quantum information, which at the end of the process is converted into classical information by measuring the final state of the quantum register.

Counters

Quantum computing will provide breakthroughs in chemistry

Just five years ago, only specialists in the field of quantum physics knew about quantum computers. However, in recent years, the number of publications on the Internet and in specialized publications devoted to quantum computing has increased exponentially. Subject